ANDALUSITE

Introduction to Hongshizhu

Andalusite and kyanite, sillimanite are homomorphic variants. Its English name, Andalusite, was derived from the first discovery of minerals in Andalusia,

Andalusia, Spain, but it was not until the discovery of gem-quality andalusite in Sri Lanka, especially in Brazil, that the first time that the andalusite was classified into the gemstone category.

The chemical composition of andalusite is Al2[SiO4]O, and the crystal is an orthorhombic (orthort) crystal system island structure silicate mineral. It is homogenous with kyanite and eve stone. It is usually a columnar crystal with a cross section close to a square. Some andalusites capture part of the carbonaceous and clay minerals during the growth process, and are oriented in the crystal. They are cross-shaped in cross section and are called hollow crystals.

The aggregates are mostly radial or granular, and are radial, commonly known as chrysanthemum stones. It is pink, rose red, reddish brown or off-white, with a lustrous glass and medium cleavage. The Moss hardness is 6.5 to 7.5, and the specific gravity is 3.15 to 3.16.

Andalusite is common in the contact zone between argillaceous rocks and intrusions, and is a typical contact metamorphic mineral. Xishan, Beijing, China, is rich in radial andalusite. Other famous places in the world include Andalusia in Spain, Tyrol in Austria, and Minas Gerais in Brazil.

The andalusite is heated to 1300 ° C to become mullite, which is a high-grade refractory material with the same use as kyanite. Light red or green transparent crystals can be used as gemstones. The empty spar is often processed into a craft ornament because it has a black cross on a pink, gray background.

There is a variant of andalusite called hollow spar. The cross section of the spar will show a black cross structure. This cross structure is caused by the fact that andalusite receives some carbon and clay when it is formed. This hollow spar is often made into a small ornament worn by people.

Andalusite is generally a columnar crystal, and its section is almost square. The crystals of andalusite are brought together to form a radial or granular shape. For the radial andalusite, it is often referred to as "chrysanthemum stone", meaning that they are as open as the petals of chrysanthemum.

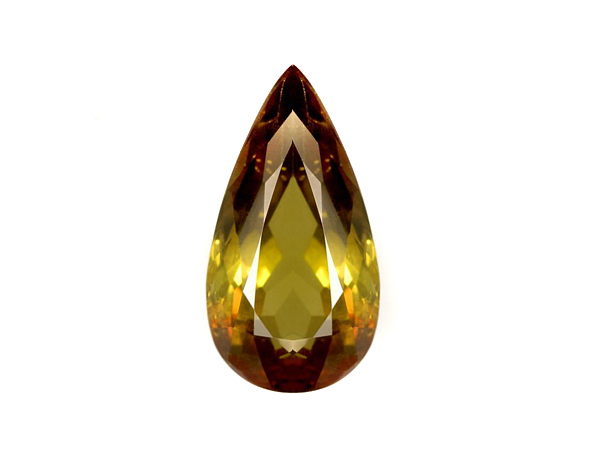

The andalusite is pink, red, purple, green, reddish brown, grayish white, grayish yellow and light green with a glass luster. Some good quality and transparent andalusite crystals are also used as gemstones.

China's development and utilization of andalusite has shown broad prospects. The use of the Chinese andalusite started relatively late. Since 78 years, the high-aluminum mineral resources such as andalusite have been prospected, evaluated and explored. The industrial requirements for it have changed according to the conditions of use.

Stone column information

Crystal form: orthorhombic double-cone crystal, the crystal is columnar.

The main simple shapes are: oblique square m, n, plane double c.

Crystal system and space group: orthorhombic system, D122h-Pnnm.

Hardness: 6.5-7.5.

Specific gravity: 3.13-3.16g/cm3.

Cleavage: Not completely cleavable.

Fracture: A slender fracture created by a cross-clear cleavage or cracking.

Color: often grayish white or flesh red, blue, green, purple is rare.

Streak: white.

Transparency: transparent.

Gloss: Glass luster.

Luminescence: None.

Other: Slightly brittle.

Distribution range

According to the ore-seeking effect of andalusite in recent years, China's mineral resources are very rich, which is conducive to the geological conditions for the formation of such minerals. Liaoning, Jilin, Qinghai, Gansu, Shaanxi, Shandong, Henan, Xinjiang, Fujian, Hubei, Sichuan, Beijing and other provinces and cities have found. In many areas, the content of andalusite minerals is high, and the mineral composition is simple, and the storage is mostly above the medium.

Industrial indicators

For the development and utilization of andalusite mines, in general, we should focus on economic benefits and propose different indicators from various perspectives. At present, there is no uniform regulation in this respect in China. Now it is jointly issued by the National Geological Bureau - (1978) No. 1201 and the Ministry of Metallurgy (78) Yejizi No. 3278: "On the arrangement of the survey and mine of the Lansing census The Notice of Design and Construction Work is briefly described as follows:

1. Classification of ore source ore (mineral quantity): 5% grade grade, grade ≥ 8%, grade II grade 5 8%.

2, the thickness of the pickable and the thickness of the stone removed are 1 meter.

nature

Mineral composition

Most of the andalusite has a patchy crystal structure. The phenocrysts contain carbonaceous, quartz, mica, metal minerals, garnets and tourmaline. Some associated minerals such as garnet, carbonaceous, etc. can be recovered by beneficiation.

Mineral characteristics

Andalusite belongs to the orthorhombic system, and the crystal extends in the shape of a rhombic cylinder along the C axis. Since the angle of the cylinder is about 89 ° C, the appearance is very similar to a square prism. The aggregates are radial and granular, and intercalated twin crystals are visible. The cylindrical solution (110) is complete. The flakes are colorless, sometimes with a slight pink hue, and the color distribution on the same sheet is often uneven, with different shades and spots. Parallel or symmetric extinction, with weak pleochroism: Npi reddish (1.629 ~ 1.639), Nm light green (1.633 ~ 1.639), Ng light green (1.637 ~ 1.650). The cross section is nearly square, and sometimes two sets of nearly orthogonal cleavage are visible. In the andalusite, there are sometimes black carbonaceous inclusions (called goethite). It can be distinguished from the meteorite by the characteristics of the multiple color of andalusite.

Internal and external microscopic features: The andalusite inclusions are mainly apatite, rutile, muscovite, graphite and various clay minerals. Some mineral inclusions also have very complete characteristic crystal forms, such as short columnar apatite crystallites and acicular rutile. The gas-liquid inclusions are also common inclusions in andalusite. In addition, the ribbons are common under the microscope. Growth structure, such as double crystal grain. The inclusions in the grit are black carbonaceous inclusions and are distributed in a cross shape.

Surface properties

Andalusite itself is not electromagnetic, but its surface properties determine the type of surface rupture bond and the degree of fracture, which is related to its crystallization chemistry. When its crystal is broken, it will produce cationic Al3+, Fe2+, etc. with high energy combination advantages. The surface of the andalusite is hydrophilic, and metal cations are present in the upper part after the crushing. The zero point PH is 7.2, which is generally higher than the silicate fracture.

The andalusite mineral consists of Al-O bonds and Si-O bonds. When the lead oxide has a pH of 9, a zero point occurs. When the quartz is at PH=2 or slightly larger than 2, the zero point appears. It can be considered that the aluminosilicate minerals have a zero point between 2 and 9, which is advantageous for their sorting and purification.

Chemical component

Andalusite is an anhydrous silicate belonging to the family of bluestone. Its chemical formula is Al2O3.SiO2 or Al2O[SiO4].

Theoretical chemical composition

Al2O3 63.1%, SiO2 36.9%, but due to metallogenic crystallization, alteration, weathering and other reasons, the lattice often contains some impurities such

as Ag, Fe, Ti, causing the chemical analysis results to deviate from the theoretical value.

Optical properties

The sheet is colorless, microstriped pink, and the color distribution is uneven.

Two-axis crystal. Np = 1.629-1.640, Nm = 1.633-1.644, Np = 1.639-1.651. 2V = -86°.

Weak pleochroism: Np-light red, Nm, Ng-light green.

Process characteristics

The industrial use of andalusite is mainly due to its high temperature resistance. After the andalusite is heated to 1,350 ° C under normal pressure, it begins to transform into acicular mullite parallel to the original crystal. The mullite crystal is the only stable form of aluminosilicate under high temperature, and its theoretical conversion rate is 87.64%.

In the process of heating and converting into mullite, the andalusite can form a good mullite network with a volume expansion of about 4%. This is an irreversible crystal transformation with higher fire resistance once converted. Refractoriness up to 1800 °C, and resistance to quenching and rapid heat, mechanical strength, strong thermal shock resistance, strong slag resistance, high load conversion point, and high chemical stability (even insoluble in hydrofluoric acid) ) and extremely strong chemical resistance.

The main purpose

In view of the physicochemical properties of andalusite, it is one of the known high-quality refractories. It is used not only as a high-grade refractory material in the smelting industry, but also as a raw material for the technical ceramics industry. It can also smelt high-strength lightweight silicon-aluminum alloys for the production of metal fibers and supersonic aircraft and spacecraft. According to reports, foreign countries still use mullite to gasify coal and make radar radomes. Crafts and decorations can also be made by some of the crystals that are well crystallized and brightly colored. Since the 1970s, andalusite has been widely valued for industrial production in China, and its application fields are rapidly expanding. The mullite formed by calcination has high refractoriness, chemical stability and mechanical strength, and is widely used in metallurgy, building materials and other industrial sectors.

Refractory

This has special benefits for metallurgical processes such as high temperature operation. The amorphous refractory material can be directly used without being burned, which can save fuel energy, and its volume stability at high temperature has a great influence on its service life. In practice, if the burnt-in material and the plastic can be used in proportion, it will contain a certain amount of clay and inorganic binder, which will cause the amorphous refractory to shrink during high temperature and cooling, cracks and flaking, and shorten the use of refractory materials. life. In order to control and reduce the shrinkage of refractory products at long-term high temperature, if a certain amount of andalusite is added to the ingredients, the above-mentioned shrinkage phenomenon of the amorphous material can be eliminated by using the characteristics of expansion stability, and the service life of the material can be extended up to five years. as long as.

Refractory brick

The andalusite is calcined and made into profiles, which can be used in key parts such as hot blast stove, hot air tower and reheating. It can also be used in a variety of auxiliary casting and handling equipment, as well as kiln facilities, high temperature aluminosilicate insulators, and sand mold fabrics. The refractory fiber made of andalusite is used as a lining, which can save 30-50% energy compared with refractory or light brick lining. In addition to reducing the fuel consumption and increasing the stability, the andalusite refractory brick can save more than 40% of the consumption of general refractory materials.

Raw materials for the production of silicon-aluminum alloy, alumina and aluminum metal: due to the high content of andalusite Al2O3, low content of oxide impurities such as iron, titanium and calcium. When used to produce silicon-aluminum alloy containing 60% aluminum, it can be used without alumina. This simplifies the production process and increases production efficiency.

Use method

In the country, the exploration work of andalusite began in 1978, and the exploration work of the andalusite beneficiation laboratory was carried out successively. The characteristics of these work are: the composition of the size of the andalusite concentrate not according to the requirements of the refractory products. Fine particles are fillers) Consider the separation process. Both use magnetic separation - flotation. Magnetic separation - re-election - flotation and other joint sorting processes.

The ore contains about 8-18% of andalusite, and the obtained andalusite concentrate contains about 55-57% of Al2O3, and the recovery rate of andalusite mineral is about 60%. The beneficiation equipment used was all equipment produced in the mid-1980s in China. South Africa is the world's largest producer and exporter of andalusite.

The sorting process adopted in South Africa is basically the same. In the process, the heavy medium cyclone is used for pre-enrichment, and then the strong magnetic separation is used to check. This is an effective beneficiation method for the production of andalusite in South Africa, and finally it can be obtained with Al2O3≥ 58%, a red and white concentrate of Fe2O3 ≤ 0.9%.

French andalusite is finely embedded. First, the ore is ground to 1.6mm to remove the magnetic material by magnetic separation method, so that the andalusite is enriched, and then purified by a heavy medium cyclone twice, and the andalusite concentrate can be obtained with Al2O358% and Fe2O31.0%.

France's Damrischa first introduced a new flotation method in 1987 with a pH of <3.5 and a pulp concentration of 15-30%. The amphesterite is floated with an alkyl sulfonate as a collector to select the highest standard andalusite concentrate, KF grade. Containing Al2O360%, Fe2O30.6%. The law applied for a European patent in 1989.

Quality Standard

The influence of useful elements and main associated elements on raw materials

Although andalusite has the same chemical formula as sillimanite and sillimanite, its crystal lattice often contains iron oxide and manganese oxide, and its color is gray and yellow. For example, the manganese-containing variant is dark green and is called manganese andalusite. The crystal structure of andalusite is a transition from kyanite to sillimanite. It is found in muddy and carbon-shale shale and is symbiotic with other minerals such as quartz, garnet,

corundum, kyanite, mica, limonite, ettringite, rutile, pyrite.

According to ore morphology and mineral composition, andalusite is divided into two types: schist and horn. The shale-type andalusite ore is composed of andalusite and garnet, cross stone and quartz agglomerate. The matrix is mainly composed of mica, fine-grained quartz and carbon, mud and iron. The ore is in the form of flakes and shale flakes. The horn-type andalusite ore is biotite and the quartz diorite is metamorphosed by hydrothermal action. Andalusite and chlorite, mica and carbon are composed of phenocrysts. The matrix consists of quartz, muscovite, sericite, biotite, and plagioclase, which are aggregates of argillaceous debris and weakly magnetic. Followed by a small amount of monomeric quartz, feldspar, tourmaline, zircon, rutile, apatite, limonite and the like.

The interior of the andalusite crystals often contains more carbonaceous and muddy inclusions and becomes an empty spar, which makes the color of the andalusite black. In view of this, for the andalusite ore with larger particle size of andalusite, since the impurities adhered to the surface of the single mineral of andalusite are relatively small to the weight of the monolith, it is easy to obtain the andalusite concentrate containing Al2O3. . On the other hand, if the size of the andalusite is small, it must be finely ground to remove impurities that are equivalent to the weight of the mineral and adhere to the surface to obtain a qualified final concentrate. Therefore, the size of andalusite crystals in andalusite ore is an important factor affecting the difficulty of selection and the process structure.

The occurrence of gangue minerals is another important factor affecting the beneficiation process and the selection index. The feldspar, argillaceous clay minerals, quartz, limonite, and biotite are cemented together, and after being in the state of cuttings, they have weak magnetic properties, so that they can be selected by magnetic separation. The Fe2O3 component in the cuttings is mainly brought into the biotite. The content of biotite in the cuttings is more, and the larger the specific magnetization coefficient, the easier it is to be selected by magnetic separation.

National standard

People's Republic of China Industry Standard YB4032-91:

(1) This standard specifies the classification, code, grade, technical requirements, test methods, inspection rules, packaging and quality certificates of andalusite concentrate. This standard applies to the andalusite concentrate obtained by the ore dressing, for advanced refractory materials, technical ceramics and silicon aluminum alloy.

(2) Citation standard: GB2007 bulk mineral product sampling, general rules for sample preparation. General provisions of GB5689 metallurgical and mineral products packaging, marking and quality certificates. GB6900 clay, high alumina refractory chemical analysis method. GB7322 refractory test method for fire resistance. GB8923.7 Dense refractory castable wire thermal expansion test method.

(3) Classification, code, grade: andalusite concentrate - the "HJ" of the two Chinese pinyin letters of "red" and "fine" is coded. According to the Al2O3 content, the andalusite concentrate is divided into three grades: HJ-58, HJ-55 and HJ-52.

(4) Technical requirements: The product granularity is determined by the supplier and the buyer, and the product shall not be mixed with foreign inclusions and physical and chemical indicators of the product.

development trend

Earth's andalusite reserves are concentrated in South Africa, France and China. Spain, Portugal, Russia, Ghana, South Korea, California, and North Carolina also have certain reserves.

The world's commercially available andalusite production is basically limited to South Africa, with an annual output of about 250,000 tons. About half of South African products are exported to Europe. The French company Damcle has a mine with an annual output of 65,000 tons. Not long ago, Damlake took over Annisley.

Andalusite refractories and Curry South Minerals. Annisley operates in Bergsfet with an annual production capacity of 60,000 tons. The product has two grades: 1 to 4 mm and 3 to 8 mm, and the product has a high Al2O3 content of 59%, all of which are used for refractory materials. Exported to the United States, Japan, Australia and Europe. The former Cullinan is operated by Reddenberg, with an annual production capacity of 50,000 tons. The product grades are K55 and K57P, and Al2O3 [2] is 55% and 57% respectively. Raw materials are exported to Europe and the Far East, mainly to the UK, Germany, Spain and Italy. Its main product in Anluf Andrafax, located in Grut Marico, is exported to Japan, Europe and the United States.

Lenore, a subsidiary of the Angloval Group, operates one of the largest mines in South Africa. The mine is located near Tabakimbe in the northern part of Mpumalange, with a production capacity of around 120,000 tons, of which 60,000 to 70,000 tons are exported, 85% are shipped from Richards Bay, and the rest are bagged from Duban issued. About 90% of the latter is sold as an abrasive. About 50,000 tons are sold to the domestic market each year, most of which is consumed in the steel industry as refractory materials. Sales are worldwide and exports are mainly in Eastern Europe and Southeast Asia. The number of processing points is not large, and a large number of special-grade products are produced by processing plants.

The Hulnik Exploration Company will start the andalusite business after acquiring the assets of Hocken Neugg. This will enable Hernik's annual production capacity to reach 36,000 tons, which is produced in the area of Pittsburgh-Borgster. In addition, Hernik is continuing to develop an annual production capacity of 20,000 tons of andalusite in the Grut Marico area. The open-pit mine of the Daml Lake Group in France is located in Grommel, Brittany, and processes 600,000 tons of ore original ore annually. With an annual output of 6.5 to 70,000 tons of concentrate. The product is supplied to the refractory industry under the brand name “Kerphalite” and has different grades of Al2O3.

China produces about 8,000 tons of andalusite in Henan and Shandong, of which 5,500 tons are exported. Chinese minerals contain a high amount of Fe2O3, which is about 1.5%. The FOB price of Xingang is roughly US$300/ton. The main reason for the impact on export costs is that no large-scale production has taken place.